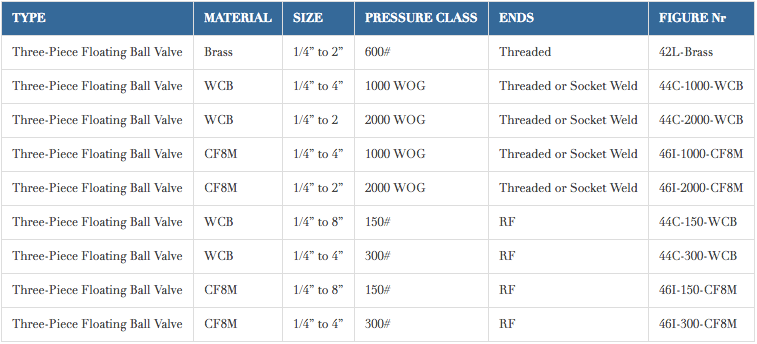

Floating Ball Valves

This product line is used primarily in the Oil & Gas, Building and construction Industries, Chemical and Petrochemical services, among others. Unimech Oil & Gas offers Floating Ball valves to provide positive shut-off while minimizing pressure drop.

Unimech Oil & Gas offers an array of materials used for this product line, including but not limited to:

- Carbon Steel such as A-105 or WCB, etc.

- Stainless Steel such as CF8, CF8M, etc.

- Low Carbon Stainless Steel such as CF3, CF3M, CG3M, etc.

- Super Stainless Steel such as CN7M (Alloy 20), CN3M (Alloy 20 modified), CT15C, etc.

- Brass like B283 grade C37700.

Unimech Oil & Gas offers a variety of trim materials including but not limited to the following:

- Ball and stem made from SS-304, PTFE seats and stem packing.

- Ball and stem made from SS-316, PTFE seats and stem packing.

- Ball and stem made from SS-316, PTFE seats and graphite stem packing suitable for fire safe design.

Design Features

- Floating Ball Valves in accordance with MSS-72 & API-608

- Two or three-piece design.

- Socket weld, threaded or flanged ends.

- Lever or Gear operated as per Customer requirement.

- Fire safe design available upon request.

- ISO-5211 top flange drilled and tapped upon request.

- Locking device available as per Customer requirement.

- Test in accordance with API-6D.